Specifications

can be used for Multipole conductor rail

safe, seamless, run smothly,highspeed,lownoise,powered way arbitrariness

Our Services

If samples are required, we can arrange for you.

If you buy a lot of our products, we will give you the discount.

If you are not clear about the installation, we can give a hand to help you solve the problem.

Product Description

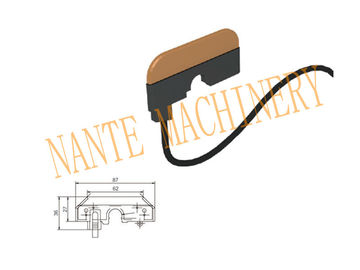

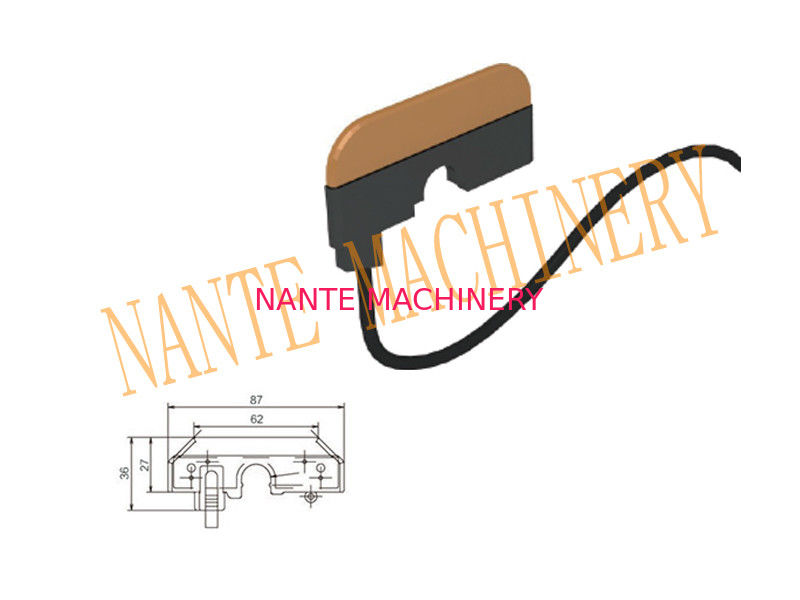

| Type |

Weight(kg) |

Material |

| H19CB-100 |

0.1 |

Copper-graphite Brush |

ABOUT NANTE MACHINERY

After 20 years rapid development, NANTE and its parents company ZHONGJIAN Group has grown into a leadingintegrated solution provider for crane and crane components in China. Dedicated to the research and development of newlifting and handling technologies, we adopt innovative ideas and design in developing new products and services. Backed upby a wealth of industrial experience on lifting industry, We can provide to customer wide range of lifting equipment andcomponents with scientific design, good safety, high performance, efficient operation and low maintenance cost. We arecommitted to help our clients to reduce investment cost, improve production efficiency, and economize energy consumption.

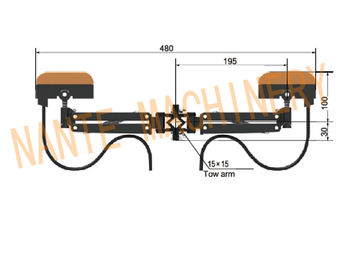

NSP-H Installation Diagram

1. Support Installion:Fix the two supports of both sides of the track(welding or bolt) and adjust to the horizontal state(add 1 or 2points to meet the length of the wiring route).Take the wiring between the two supports as the benchmark,the rest supports should

be installed according to the standard distance(1800 mm for bolt and 2000mm for welding), to ensure the depth of parallelism of

the conductor rail between the height of the track less than 10 mm..

2. The connection part of the conductor and the connector should be polished with abrasive cloth to remove the oxide layer,applythe electrical conductive pastes and screw the bolt,double checkif the seam of the guides is in minimum.

3. The installation of the current collector: Dedine the length of the tow arm unit according to the poles ofelectrode and installation

space. 120±5mm distance should be ensured in distance between the upper end and down end of the conductor rail(refer to theinstallation diagram of the conductor rail for more details)

4. End cap: Install the end caps on both sides and tighten them with rubberized fabric.

5. Inspection: Inspect the depth of parallelism between the conductor rail and operation trackof the hoisting unit and control the

depth within 20mm, make a test run and check the running state of the flake passing through each nodal point,tighten all thefastening piece if some problems occurs,dry run one month without interval and tighten all fastening pieces again.

NSP-H System Installation